Thanks to Colin G0PHO and Bradley M0XBW for the on-air test today - and enjoyable mobile QSOs! I can confirm that the hands-free kit is working well.

I thought I would add this photo of the radio in the car, although it is a little confused because I still have the wiring for the FT60 handheld here too. There are two toggle switches taped to the cigarette lighter plug, bottom right. the left hand one is for the DMR radio.

The "well" in which the radio sits is in the centre console and the TX/RX switch is just in-front of the gear lever, so it is easy to find without looking.

I use the internal battery of the radio. In the old days you could get more RF power out by running your handheld on 10 or 12V derived from the vehicle supply, but the modern radios produce just as much output when running from internal batteries. Also, this approach prevents alternator whine and ignition noise from the car electrical system appearing on the transmitted or received audio.

The cigarette lighter plug here is a mobile phone charger and nothing to do with the radio set-up.

There are a couple of general comments I would like to make about the TYT MD380, in case you are thinking of getting one. I find the display quite difficult to see out doors in daylight - quite impossible if the sun is shining on it. The colour display is very pretty indoors, when the backlight is on, but goes completely blank when the back-light switches off. I find I am constantly twiddling the volume, or pushing the power up-down button just so the light will come on and I can read the screen.

Also the radio is supplied with a charging stand - with a nice LED that is red when charging and goes green when it is cooked. I like that, but it is powered by one of those horrid little plug-top power supplies and it generates S9 noise right across the 50MHz band - ughh! I don't think it has any filtering in it at all, such a shame for an amateur radio product, and makes you wonder about the safety of the device if they can't be bothered to meet EMC requirements. So no chance of using six meters when the radio is charging.

73

Hugh

Search This Blog

Wednesday, 31 May 2017

Sunday, 28 May 2017

Hands-free kit for TYT MD380

I have finally got round to it!

To my shame I see it was nearly a year ago that I worked out the microphone and speaker connections on my TYT MD380 handheld - see the blog here:

Mic and speaker connections for TYT MD380

I have a home-made hands-free set up for operating mobile with my analogue handheld (an FT60E) and I would like to use something similar for the digital radio.

The microphone is a small electret condenser capsule, mounted on a microphone boom of galvanised iron wire (coat-hanger wire!) which is attached to a baseball hat. The microphone is quite close to the mouth, but not directly in front to avoid breath-blast. When I made my first version, I stitched the wire to the front of the cap, which was quite time consuming. The current one is glued to the back of the brim with hot-melt glue. Not very pretty, but quite quick to do.

The transmit switch is a toggle switch that is taped to the side of a cigarette-lighter plug that is located very conveniently beside the gear-change stick. This makes it very easy to flip between TX and RX without taking my eyes off the road. And also doesn't involve drilling any holes in car.

I use a Diamond dual-band mobile antenna on the motor car, mounted on the tailgate and connected to the radio via RG58, a BNC and one of those BNC - SMA adaptors.

On the radio, under a plastic cover on the right-hand-side are two sockets, a 2.5mm diameter jack and a 3.5mm diameter jack. These are dual purpose, the 2.5mm one is used for the speaker connection, the 3.5mm is used for the microphone, and the radio is put into transmit by connecting the ground connection of the microphone to the ground connection of the speaker. The two sockets are also used for a USB type serial link for programming the radio - so don't connect to the unused terminals on the connector they are for data transfer. I used a cut-down, ready-made, 2.5mm audio cable, to avoid soldering to a rather fiddly plug.

So here is a diagram showing the connections to the radio. Note how the microphone positive is connected to the ring of the 3.5mm jack, not the tip. Leave the tip unconnected. Also leave the ring on the 2.5mm jack unconnected, these are the data connections. See how the transmit/receive (PTT) switch is wired between the speaker and microphone grounds. It is important for the microphone to be wired the correct way round, because the radio provides power for the FET amplifier in the capsule.

Here is a picture of the wiring before I covered it all with electrical tape. We don't want any short circuits. But it is always best to test it all before covering it with heatshrink or insulting tape.

Here is the complete set-up. A more glamorous baseball cap would do wonders for the appearance of the equipment ... so would a more glamorous radio ham.

A note about the loudspeaker: I use a cheap car radio speaker because it is in a nice plastic pod, which I can put on the centre console of the car. The radio specification calls for a 16 ohm impedance loudspeaker. The car radio speaker is clearly a 4 ohm part. The radio does seem to work ok with an 8 ohm speaker, but I thought 4 ohms was pushing it a bit. I used a transformer to convert the impedance. I am using just the secondary of an audio output transformer. The winding has a centre-tap and I am using it as an autotransformer. The radio is connected across the whole winding, the speaker is connected between one end and the centre-tap. This gives a 4:1 impedance conversion. The primary of the transformer is left unconnected. Hopefully you will be able to find a more suitable speaker and not have to bother with this!

Testing: I first checked the speaker connections, plugging the 2.5mm plug in and listening to the World-wide talk-group on the local repeater. When all was working on the receive side, I made sure the TX/RX switch was "off" and plugged in the 3.5mm jack. Now, on our local repeater GB7AS, we have a special Talk-group on Slot 2 which echos back the transmit audio after a short delay, for people to test their radios. This is called TG9990 Echo Test. If you don't have this, then you will have to get a friend to listen to your audio and check it is working well. you can see if the TX/RX switch is working because the LED on the top of the radio goes red in transmit. Have fun!

73

Hugh M0WYE

To my shame I see it was nearly a year ago that I worked out the microphone and speaker connections on my TYT MD380 handheld - see the blog here:

Mic and speaker connections for TYT MD380

I have a home-made hands-free set up for operating mobile with my analogue handheld (an FT60E) and I would like to use something similar for the digital radio.

The microphone is a small electret condenser capsule, mounted on a microphone boom of galvanised iron wire (coat-hanger wire!) which is attached to a baseball hat. The microphone is quite close to the mouth, but not directly in front to avoid breath-blast. When I made my first version, I stitched the wire to the front of the cap, which was quite time consuming. The current one is glued to the back of the brim with hot-melt glue. Not very pretty, but quite quick to do.

The transmit switch is a toggle switch that is taped to the side of a cigarette-lighter plug that is located very conveniently beside the gear-change stick. This makes it very easy to flip between TX and RX without taking my eyes off the road. And also doesn't involve drilling any holes in car.

I use a Diamond dual-band mobile antenna on the motor car, mounted on the tailgate and connected to the radio via RG58, a BNC and one of those BNC - SMA adaptors.

On the radio, under a plastic cover on the right-hand-side are two sockets, a 2.5mm diameter jack and a 3.5mm diameter jack. These are dual purpose, the 2.5mm one is used for the speaker connection, the 3.5mm is used for the microphone, and the radio is put into transmit by connecting the ground connection of the microphone to the ground connection of the speaker. The two sockets are also used for a USB type serial link for programming the radio - so don't connect to the unused terminals on the connector they are for data transfer. I used a cut-down, ready-made, 2.5mm audio cable, to avoid soldering to a rather fiddly plug.

So here is a diagram showing the connections to the radio. Note how the microphone positive is connected to the ring of the 3.5mm jack, not the tip. Leave the tip unconnected. Also leave the ring on the 2.5mm jack unconnected, these are the data connections. See how the transmit/receive (PTT) switch is wired between the speaker and microphone grounds. It is important for the microphone to be wired the correct way round, because the radio provides power for the FET amplifier in the capsule.

Here is a picture of the wiring before I covered it all with electrical tape. We don't want any short circuits. But it is always best to test it all before covering it with heatshrink or insulting tape.

Here is the complete set-up. A more glamorous baseball cap would do wonders for the appearance of the equipment ... so would a more glamorous radio ham.

A note about the loudspeaker: I use a cheap car radio speaker because it is in a nice plastic pod, which I can put on the centre console of the car. The radio specification calls for a 16 ohm impedance loudspeaker. The car radio speaker is clearly a 4 ohm part. The radio does seem to work ok with an 8 ohm speaker, but I thought 4 ohms was pushing it a bit. I used a transformer to convert the impedance. I am using just the secondary of an audio output transformer. The winding has a centre-tap and I am using it as an autotransformer. The radio is connected across the whole winding, the speaker is connected between one end and the centre-tap. This gives a 4:1 impedance conversion. The primary of the transformer is left unconnected. Hopefully you will be able to find a more suitable speaker and not have to bother with this!

Testing: I first checked the speaker connections, plugging the 2.5mm plug in and listening to the World-wide talk-group on the local repeater. When all was working on the receive side, I made sure the TX/RX switch was "off" and plugged in the 3.5mm jack. Now, on our local repeater GB7AS, we have a special Talk-group on Slot 2 which echos back the transmit audio after a short delay, for people to test their radios. This is called TG9990 Echo Test. If you don't have this, then you will have to get a friend to listen to your audio and check it is working well. you can see if the TX/RX switch is working because the LED on the top of the radio goes red in transmit. Have fun!

73

Hugh M0WYE

Friday, 26 May 2017

Ermine Moth

A closer look reveals that the culprit is not a spider, but lots of caterpillars.

This last happened in May 2011 (I still have the photos I took then!), and a bit of research then revealed that these are ermine moth caterpillars, and their host plant, is the spindle tree.

On the Wikipedia page there is a picture of the moth, but I have never knowingly seen one of the adults. https://en.wikipedia.org/wiki/Yponomeuta_cagnagella

The plant has been completely stripped of leaves, but in 2011 the bare twigs sprouted new leaves after the caterpillars had gone. It can't do the spindle tree much good, but it does seem to recover. So I hope it will do so again this year. I notice that the parts of the hedge which are affected are all close to telegraph poles - not sure if that is coincidence.

Since I travel this route almost every day, I think I would have noticed if there had been similar tents in the hedge between 2011 and 2017, but I don't recall seeing any. So that raises the question is this a regular event occurring every six years? or is it just the climatic conditions have been ideal for the caterpillars? At the moment ... we just don't know ...

73

Hugh M0WYE

Wednesday, 3 May 2017

Bass Pedalboard Microswitches

A bit more on the bass pedalboard project.

I tried some different switches ...

I found the smallest ones were the best. They are the quietest in operation.

They are arranged in pairs. The idea is to try and use velocity sensing - the harder the pedal is played the less time between the switch closures. That's the theory ....

In practice I found it quite hard to match the pedals, as the exact point at which the contacts close depend on the spacing of the pedal and positioning of the switch. my woodwork may not be good enough for this!

Here's a very slow pedal press, at 130mS long gap between the two switches closing.

Here's the fastest I could do by really stomping on it ... about 1mS. But here you can start to see the "switch-bounce". I will filter that out, but it may be hard to separate the "bounce" from the "stomp" at these short times.

Here's a medium sort of pedal press at about 15mS. There is a distinct logaraithmicness to the range of times I was getting. it will be a bit of a challenge to get the software to measure these times with out delaying the note-on command appreciably.

73

Hugh M0WYE

I tried some different switches ...

I found the smallest ones were the best. They are the quietest in operation.

They are arranged in pairs. The idea is to try and use velocity sensing - the harder the pedal is played the less time between the switch closures. That's the theory ....

In practice I found it quite hard to match the pedals, as the exact point at which the contacts close depend on the spacing of the pedal and positioning of the switch. my woodwork may not be good enough for this!

Here's a very slow pedal press, at 130mS long gap between the two switches closing.

Here's the fastest I could do by really stomping on it ... about 1mS. But here you can start to see the "switch-bounce". I will filter that out, but it may be hard to separate the "bounce" from the "stomp" at these short times.

Here's a medium sort of pedal press at about 15mS. There is a distinct logaraithmicness to the range of times I was getting. it will be a bit of a challenge to get the software to measure these times with out delaying the note-on command appreciably.

73

Hugh M0WYE

Emergency Light Power Consumption

I was given a couple of emergency lights which were being taken out of service because the batteries had deteriorated.

I wondered about installing one above the stairs in my home, as it would be a useful safety feature in the event of a power cut. But how much power does one of these things use?

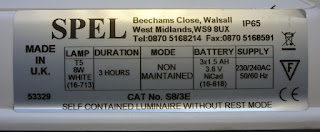

The "ratings plate" gave no indication. The 8 Watts referred to is the power of the fluorescent lamp - but that only runs when the mains power is off. There is no indication of how much power is used from the mains to charge the batteries.

I decided to measure it using one of those plug-in mains power meters. And was alarmed to see a figure of 40 Watts displayed. Now later I realised that there was a very small decimal point in between the digits and the actual level is more like 3.5 or 4.0 Watts! But even that is still a significant amount of power when the device is on 24 hours a day, 7 days a week. It works out at 35 kilowatt hours each year - or a few pounds-worth of electricity.

Some of my colleagues suggested that the charge circuit would probably shut off once the batteries were charged, so then the consumption would drop. I took a look inside the case, but the circuit looked suspiciously simple - so how does it work?

There is a mains transformer, and a watty resistor (R1). There is another, smaller transformer and some components that probably form a invertor circuit to light the fluorescent lamp. But there is very little in the way of logic circuitry - and the relay RL1 is conspicuous by it's absence!

I wondered about installing one above the stairs in my home, as it would be a useful safety feature in the event of a power cut. But how much power does one of these things use?

The "ratings plate" gave no indication. The 8 Watts referred to is the power of the fluorescent lamp - but that only runs when the mains power is off. There is no indication of how much power is used from the mains to charge the batteries.

I decided to measure it using one of those plug-in mains power meters. And was alarmed to see a figure of 40 Watts displayed. Now later I realised that there was a very small decimal point in between the digits and the actual level is more like 3.5 or 4.0 Watts! But even that is still a significant amount of power when the device is on 24 hours a day, 7 days a week. It works out at 35 kilowatt hours each year - or a few pounds-worth of electricity.

Some of my colleagues suggested that the charge circuit would probably shut off once the batteries were charged, so then the consumption would drop. I took a look inside the case, but the circuit looked suspiciously simple - so how does it work?

There is a mains transformer, and a watty resistor (R1). There is another, smaller transformer and some components that probably form a invertor circuit to light the fluorescent lamp. But there is very little in the way of logic circuitry - and the relay RL1 is conspicuous by it's absence!

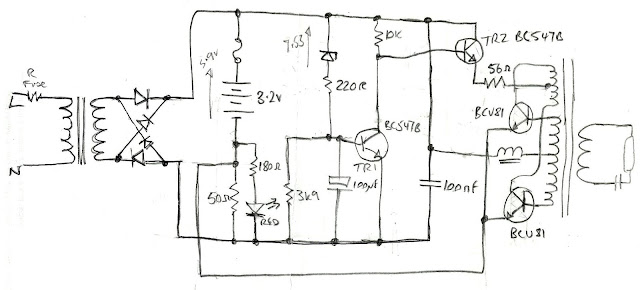

So after a few hours of work with a magnifying glass, and a resistance meter I worked out the circuit is as shown below.

The mains comes into the mains transformer and passes through a bridge rectifier. The supply at this point measures about 10.3 Volts. The charge circuit is really simple: There is a 50 ohm wire-wound resistor which limits the current into the 3.6 Volt battery. There is a red LED across the 50 ohm resistor, which lights up to indicate that there is Voltage being dropped across the resistor, and hence current flowing into the battery. With 3.6V across the battery, there is 6.7 Volts across the resistor - using ohms law, the charge current works out to be about 134mA. With fully charged NiCds the battery Voltage will rise a little, but the charge current is unlikely to be less than 120mA. So the charge circuit consumes about 1.3 Watts all the time - even when the batteries are fully charged.

The rest of the circuit uses very little power because TR2 is switched off during charging. The zener diode, ZD1, measures about 7.5 Volts, so with a 10.3 Volt supply, the base of TR1 has about 2.5V on it and will therefore conduct from collector to emitter - that, in turn, pulls the base of TR2 low and switches it off.

When the mains supply goes off, no current flows back into the transformer because of the bridge rectifier, but the supply Voltage drops to 3.6V, and this is much less than the zener Voltage so TR1 turns off, TR2 turns on, and the power oscillator, formed around the two BCU81 transistors and a rather complicated little transformer, springs into life.

So I worked out that the charge circuit uses about 1.3 Watts, and yet the measured power consumption was 3.5 Watts. How so? The rest of the power must be wasted in the mains transformer, which does get quite warm to the touch after it has been on for a while. Indeed the whole metal case of the lamp feels warm - which also suggests that there is some wasted power. Many buildings have a considerable number of these emergency lights.

I would like to think that more modern designs with LED lights would use less power, but the figure is seldom quoted in advertising or in catalogues. If the charge circuit were made to shut off when the batteries were charged, then other battery technologies could be used, such as NiMh or Lithium Ion - Nickel Cadmium cells are one of the few types which can be continuously charged in this way.

73

Hugh M0WYE

Subscribe to:

Comments (Atom)